As a long-standing innovative partner to the tobacco industry, Körber develops outstanding solutions that set new standards. Körber is playing a key role in shaping the industry's transformation, which is increasingly focused on alternative products to traditional cigarettes. A technological highlight in this transformation is the Multi Segment Maker. Why the MSM is perfectly suited to the transformation of the tobacco industry is explained by our experts Kai Karstens and Carsten Wulf.

The tobacco industry is undergoing a fundamental transformation, moving its business model into a new era. This shift aligns with the changing habits and behaviors of end consumers. Newly developed Tobacco Heated Products (THP), in which tobacco is heated rather than burned, are considered the innovative alternative to traditional cigarettes.

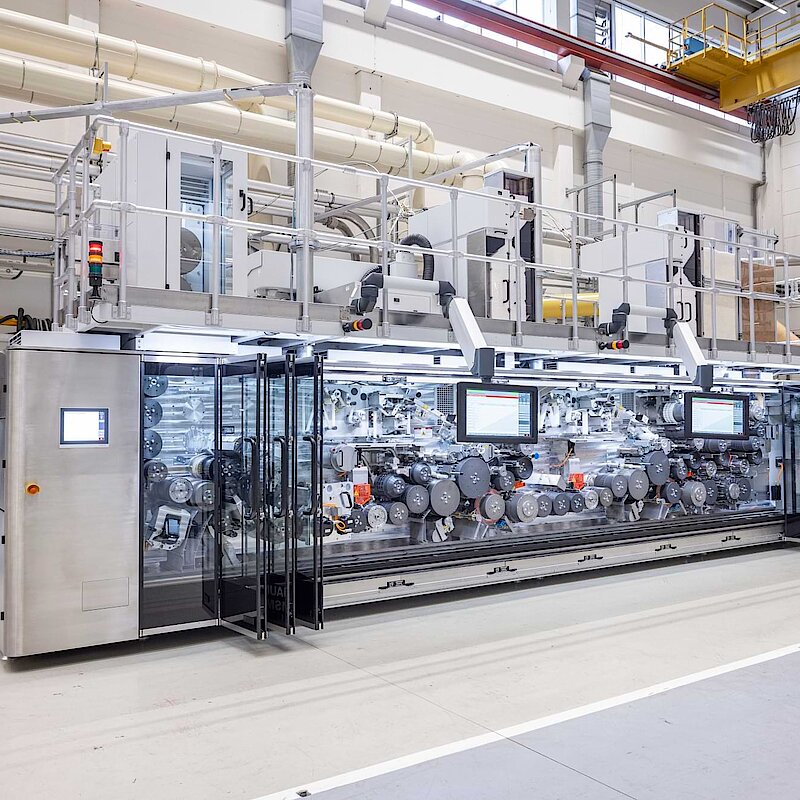

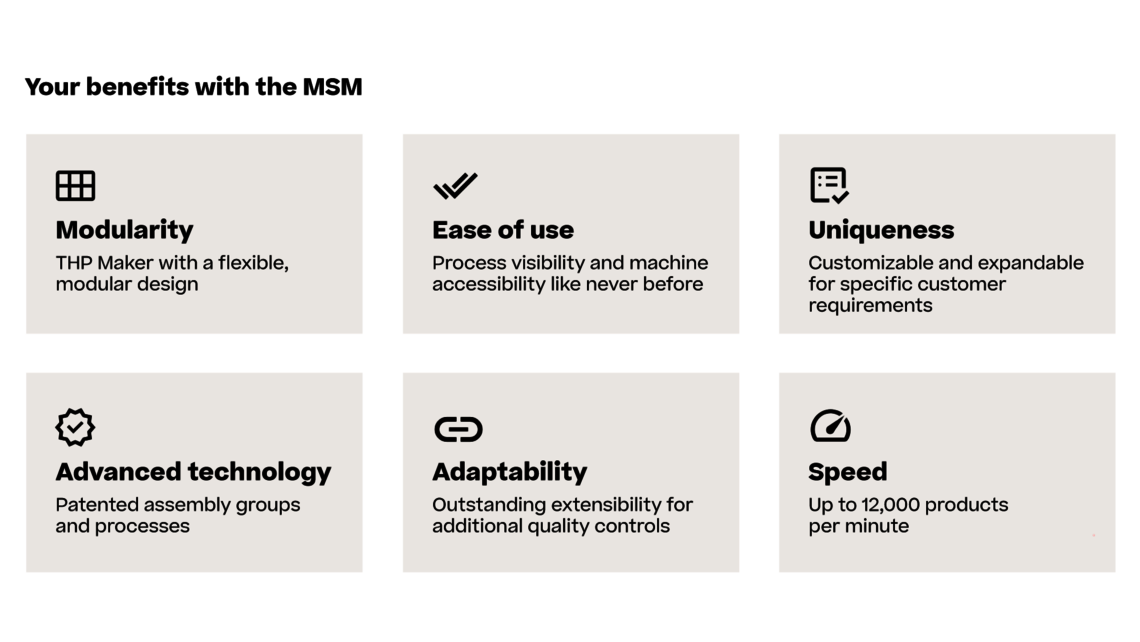

This fundamental market shift also demands groundbreaking technological innovations. Körber is taking a leading role in this process. A unique response to the changing market demands is the Multi Segment Maker (MSM), which can be configured individually to meet specific customer needs. The MSM is designed for the production of "Heat Sticks“ - tobacco sticks used in tobacco heaters.

What makes it a true flagship in Körber’s product portfolio? Kai Karstens (Executive Vice President Global Sales & Account Management) and Carsten Wulf (Technical Sales Specials) reveal the answer in this interview. They provide insights into the development process, the close collaboration with customers, and the forward-thinking modular machine concept of the MSM.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/0/csm_Web_Large-Korber_NL_200422_00092_a107841d9c.jpg)