- Insights, stories & events

- Pharma & life sciences insights

Pharma & life sciences insights

Discover the visionary strategies and impactful ideas that are shaping the pharmaceutical and biotech industries, driven by Körber's talented innovators. Explore our insights on Pharma 4.0, smart factories, IoT solutions, and digital transformation.

Case study

Everything, effortlessly, in one place

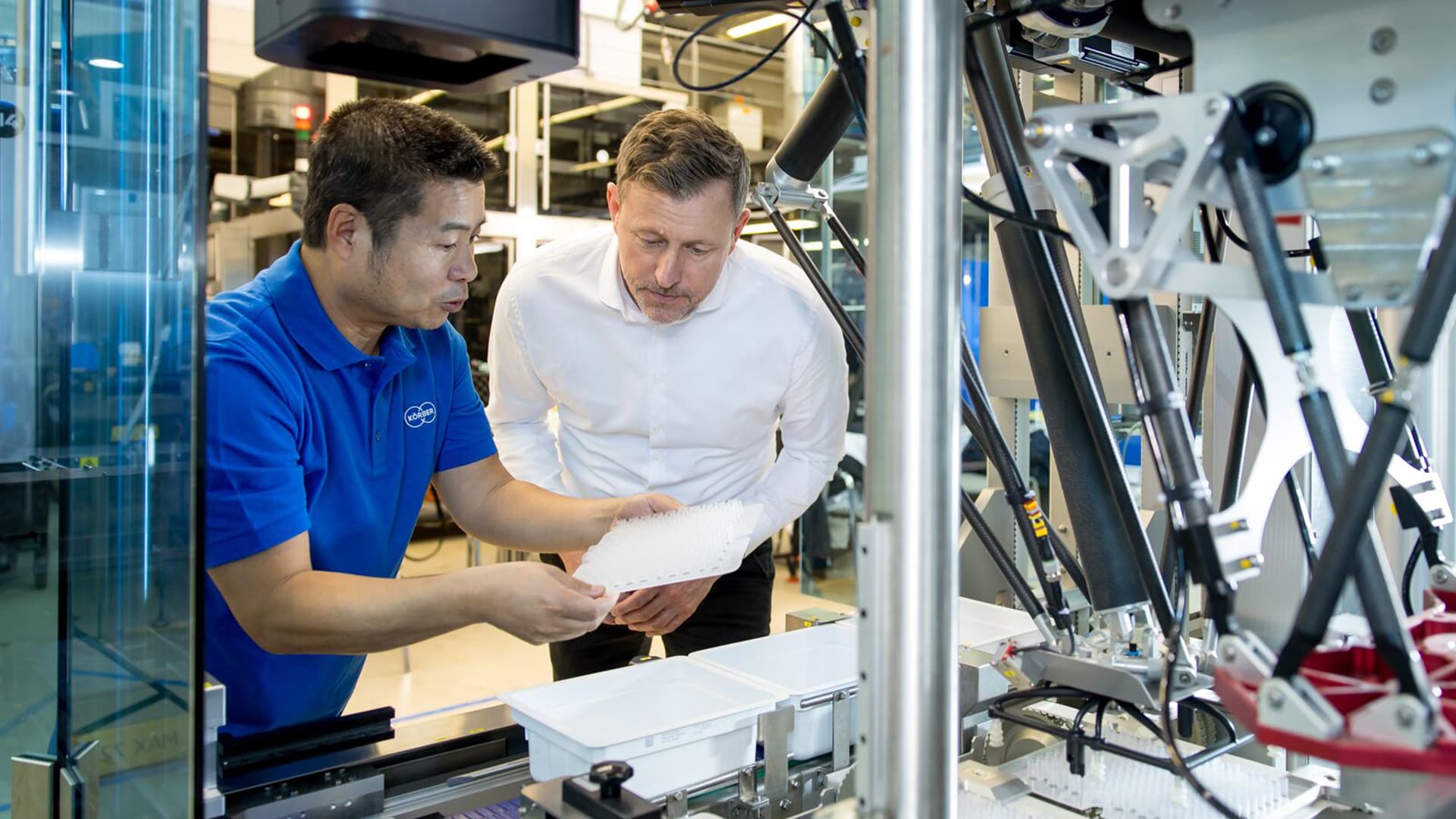

At Körber, we understand the complexity of your operations and the need for an integrated approach. Our ecosystem combines advanced hardware, cutting-edge software, and pharma expertise into a seamless platform. By connecting these elements, we simplify intricate processes and ensure harmonious production.

Learn how the Körber Ecosystem can empower your businesses to give you the edge, stay competitive and master complexity in a highly regulated industry.

Explore our thinking

News, trends and expert perspectives on pharma and life sciences, from across our business.

Pharma & life sciences events & resources

Unlock Körber’s expertise with our insightful events, resources and case study stories.

Connect with us

Let’s talk about future-ready solutions for your business.

Contact